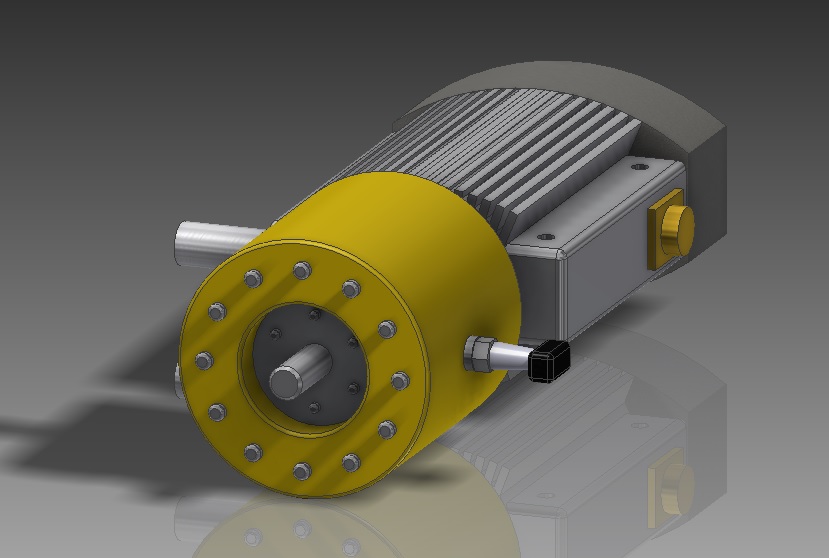

CRE Range Extender = Ceramic Rotary Engine + Electric Motor:

The Ceramic Rotary Engine is a small, compact, fuel efficient and powerful Internal Combustion Engine.

When coupled with a small, compact and powerful Switched Reluctance Electric Motor the resulting combination should possibly be the smallest, most compact, fuel efficient and very powerful range extender – ideal for use in electric airplanes for long distance travel:

Why need a range extender? Limited range is a common problem with electric airplanes and electric vehicles which has stunted their growth in various transportation markets. A range extender will increase range and enable air and land travel over very long distances across the world:

IEEE Spectrum (November 2021): Electric Airplanes Won’t Make Much of a Dent in Air Travel for Decades to Come. Reason: Batteries are nowhere near able to sustain wide-body airliners over flights measuring in the thousands of kilometers.

Why haven’t electric planes taken off yet?

Why We Still Don’t Have Electric Planes

Why use the Ceramic Rotary Engine in a range extender? Not only is it the smallest, compact, fuel efficient and powerful Internal Combustion Engine, it can also operate at very high temperatures (>9000C) which should enable the use of renewable fuels as well as reduce toxic emissions due to the complete combustion of fuels:

CRE Engine/Range-Extender For Electric Airplane Use:

- The high temperature CRE engine can readily burn renewable hydrocarbon fuels (e.g. vegetable oils and sustainable fuels).

- The CRE Engine can power the electric motor in the range extender.

- A bank of range extenders can be used to produce electricity in order to operate several turbofans of an electric airplane for international travel:

https://afdc.energy.gov/fuels/biodiesel_production.html

https://www.caranddriver.com/news/a37872650/formula-1-auto-racing-sustainable-fuel/

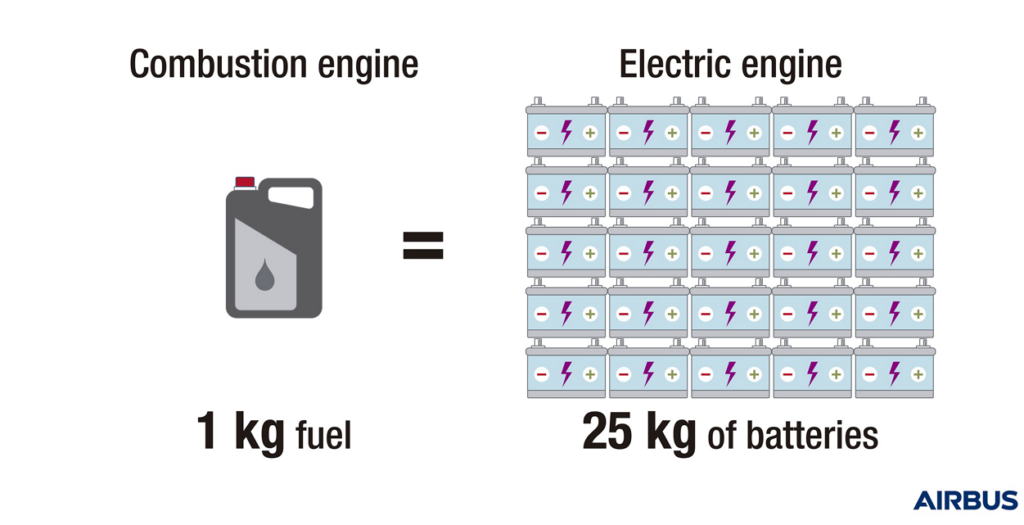

- Why Hydrocarbon Fuels? Because they have more than 10 to 20 times the energy, pound for pound, than batteries do:

- Safety can be enhanced by using two or more CRE Range Extenders in an electric airplane which will add redundancy and increase safety margins thus reducing or even eliminating the need for dangerous batteries potentially reducing a fire hazard.

- Using supercapacitors instead of batteries will reduce weight concerns for electric airplanes and supercapacitors can be safer than batteries.

- Green Emissions from Exhaust? Possible Scenario:

- High temperature combustion (>9000C) in the Ceramic Rotary Engine should result in almost complete# oxidation of hydrocarbon fuels producing carbon dioxide (CO2), nitrogen dioxide (NO2) and water vapor.

- As CO2 and NO2 are partially soluble in water, the water vapor in the exhaust of the ceramic rotary engine could contain a solution/mixture of carbonic and nitric acids.

- The exhaust from the ceramic rotary engine could be fitted with a removable cartridge containing a packed bed of calcium oxide (CaO). Carbonic and nitric acids in the exhaust would react with the CaO to produce calcium carbonate and calcium nitrate.

- The cartridge could then be emptied and the contents used as fertilizers+. A fresh cartridge of CaO can be inserted into the exhaust from time to time. Could this scenario possibly remove the need to discharge exhaust CO2 gases into the atmosphere?

- Metal IC engines, on the other hand, operate at lower temperatures (<4000C*) producing incomplete and partial# oxidation products such as toxic carbon monoxide and some unburnt hydrocarbons. That is why Metal IC engines need a catalytic converter** to convert carbon monoxide and unburnt hydrocarbons to carbon dioxide.

Sources cited:

Complete & Incomplete Combustion#

https://www.cars.com/articles/should-i-worry-about-how-hot-my-engine-is-running-1420680334271/*

How catalytic converters work**

https://phys.org/news/2016-08-electric-airplanes-batteries.html

https://newatlas.com/aircraft/aura-aerospace-powercell-evtol-ultracapacitor-hybrid/

https://www.arrow.com/en/research-and-events/articles/its-a-supercapacitor

https://www.experimentalaircraft.info/articles/aircraft-electrical-systems-9.php

https://simpleflying.com/sustainable-aviation-fuel-airlines/

https://www.planeandpilotmag.com/news/pilot-talk/2021/10/14/skeptical-about-electrical/

https://theecologist.org/2021/aug/27/jet-zero-and-politics-technofix

https://leehamnews.com/2021/07/08/the-true-cost-of-electric-aircraft-part-2/